CMM

Coordinate Measuring Machines (CMMs) are fundamental tools in modern manufacturing. They precisely measure the geometry of physical parts by sensing discrete points on the surface of the workpiece with a probe. CMMs are essential for quality control, ensuring that manufactured parts meet design specifications and tolerances. They come in various types, including bridge, cantilever, and horizontal arm, each suited for different applications. Advanced CMMs offer automated measurement routines and sophisticated software for data analysis.

Wenzel

Precise, accurate measurement results are crucial to all quality assurance systems. We combine a highly accurate, all-granite CMM frame with cutting edge probing technology to deliver a reliable, fast measuring solution. This combination can be easily adapted to each customer requirements ensuring our CMM machines remain a dynamic, integral part of your quality control systems in any industry sector. Our largest LH CMM sizes are available in Bridge or Gantry design.

Retrofit

Most CMM frames are not subject to high levels of wear & tear and remain serviceable often for decades. However, software, control systems and sensors can quickly become outdated as new faster and more capable ones are introduced. Upgrading your CMM can give it a new lease on life. A new scale and encoder package with a new controller will make your CMM more accurate. New software can make your CMM easier to use.

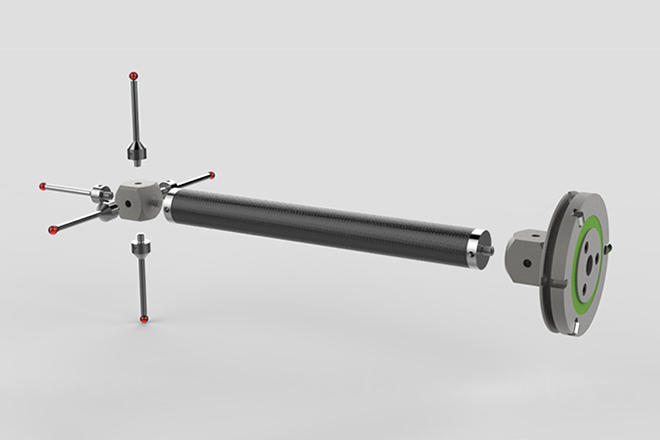

Roundness

Roundness describes how closely the form of an object approaches a perfect circle. It is a critical parameter in manufacturing, especially for components where rotational precision and performance are key, such as bearings, shafts, and precision optics. Deviations from perfect roundness can lead to vibration, noise, increased wear, and reduced efficiency in mechanical systems. High-precision roundness measurement is essential in ensuring the quality and performance of these components.

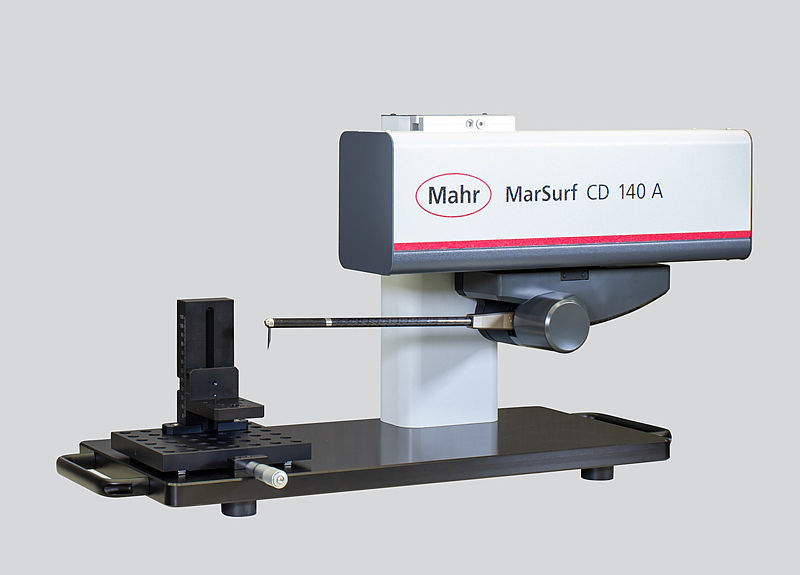

Roughness

Surface roughness is a measure of the fine irregularities in the surface texture of an object. It's quantified by the vertical deviations of a surface from its ideal form. High roughness can lead to increased friction, wear, and reduced performance in components. Therefore, controlling surface roughness is crucial in many manufacturing processes, including those in the automotive, aerospace, and electronics industries. Various parameters, such as Ra, Rz, and Rq, are used to quantify surface roughness.

Contour

Contour measurement involves quantifying the shape of a feature or part. It goes beyond simple dimensions like length or diameter to describe complex curves and profiles. Contour measurement is crucial in industries where the precise shape of a part is critical to its function, such as in the manufacture of turbine blades, lenses, and molds. Specialized instruments, such as contour measuring machines, are used to accurately measure these complex shapes and ensure they meet design specifications.

VMM

Vision Measuring Machines (VMMs) are optical inspection systems that use cameras and precision optics to capture magnified images of a part. These images are then processed to extract dimensional measurements. VMMs are particularly well-suited for measuring small, delicate, or complex parts, and are widely used in electronics, medical devices, and precision engineering. Their non-contact nature prevents damage to the parts being measured, and they can provide fast and accurate measurements.

Profile Projector

Profile projectors, also known as optical comparators, are instruments that project a magnified shadow of a part onto a screen. This allows for precise measurement of its dimensions and contours. They are commonly used in quality control for small parts with intricate shapes, such as those found in the electronics and precision mechanics industries. Profile projectors are valuable for their ability to inspect and measure features that are difficult to access with traditional measuring tools.